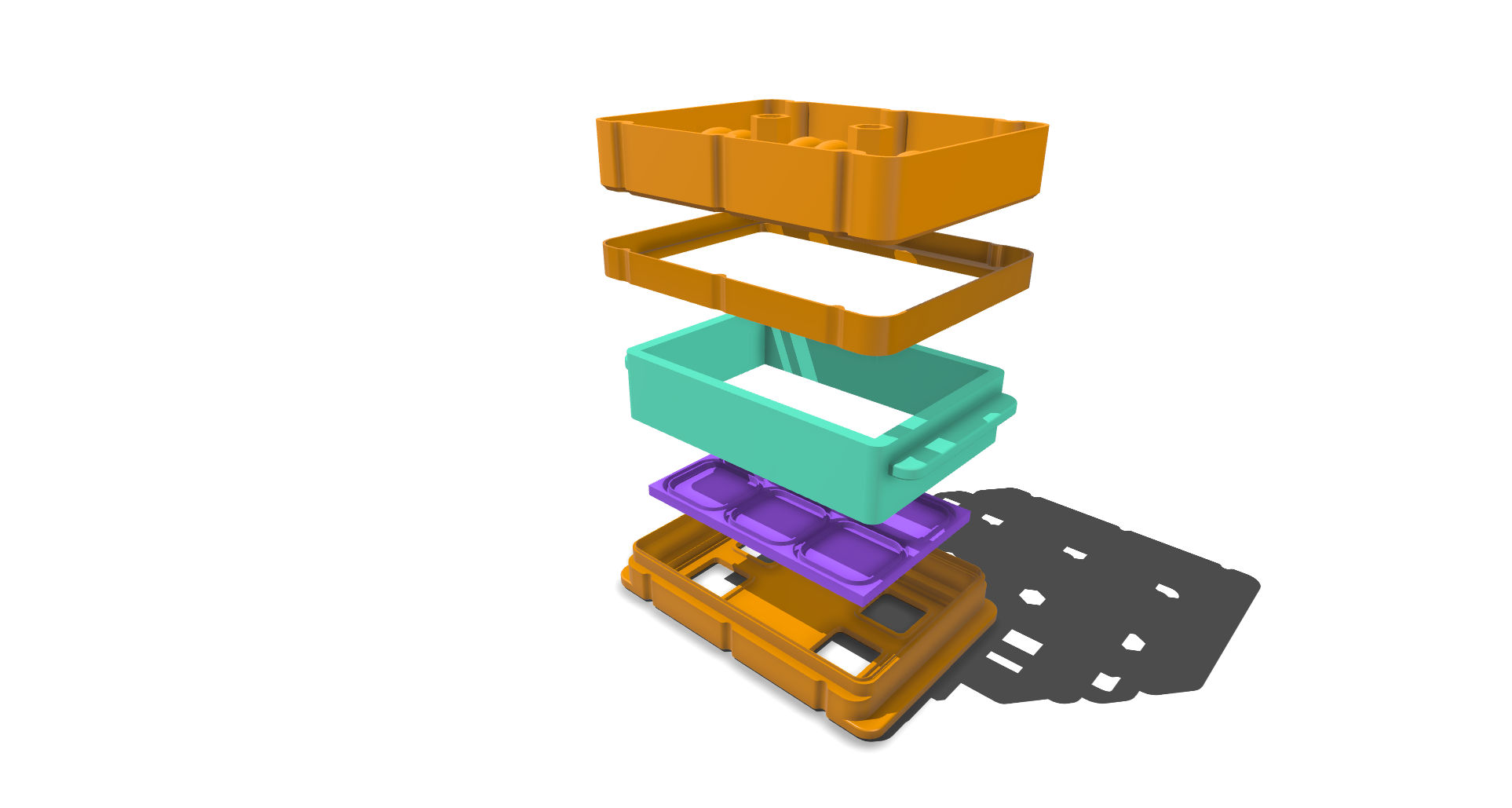

Mold ’N’ Make V1

We have simplified the manufacturing process by creating our own IN HOUSE mold system and tools. The Mold ´N´ Make system provides adjustability to different project needs, from single molds to molds for making multiple pieces. It was designed to handle the complex shapes of artisan keycaps, which often require several intricate molds. However, this system can also be used for other applications that involve creating silicone pour molds for resin and rubber casting.

Our aim was to make the design centralized as we optimize the time it takes to create new molds for new piece designs. This system is also user-friendly and helps reduce material waste.

UNIVERSAL

Designed from the ground up to be easily 3D printed and part-swapped. The system can be easily resized to fit many scales and applications making silicon mold making easier.

We took in consideration many silicon rubbers and its properties. From high viscous and self degassing to low viscous, so leaking and demolding is no problem

ADAPTABLE

IT can be used to adjusted for multiples heights according to the project.

if more than one mold is needed it can be used with a reservoir to preserve the exact height for each mold in addition to provide a free mess silicon pour.

EASY SWAPING

Multi-part molds can be easily achieved by swapping the copy bases. Improving quality reducing time between mold making.

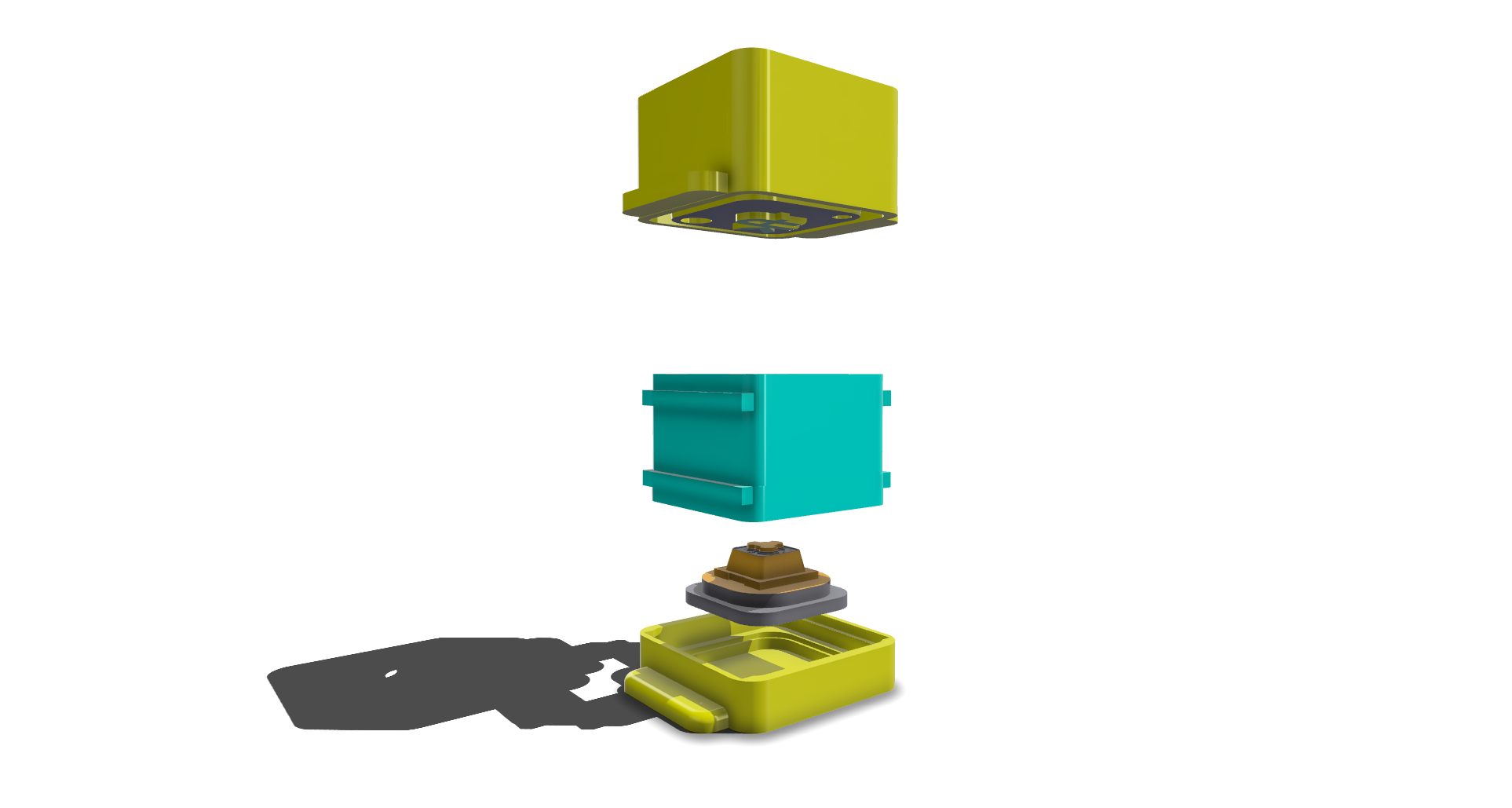

UNDERKEY MOLD TOOL

OPTIMIZE PROTOTYPING

Every detail that constitutes this mold system was designed for effectively produce functional prototypes in the shortest amount of time with no added complication. From solutions for demolding, reusability and waste reduction to few post processing of the molds itself so they can be used as quick as possible at production and optimize prototyping cycles.

Master Mold Tool

See it in action

Used to produce master for a clay sculpted piece so it can be resin casted.